Achieve the highest-quality, solvent-free end product – regardless of input – when you partner with CPM|Crown. As a leader in oilseed extraction for 75+ year, we provide the technical expertise, guidance and proven technologies to improve current processes and develop new products. Meet all your needs with our full range of drying and desolventization equipment, including continuous vacuum dryers and energy-efficient vertical dryers.

For every application, a proven solution.

CONTACT A DRYING/DESOLVENTIZATION EXPERTSPECIALTY DRYING & DESOLVENTIZATION

High-performance drying and desolventization for every application.

闪蒸干燥机

No moving parts—for applications where a fine end-product is desired

- Delivers a fine end product that does not require further milling

- Dry and de-agglomerate in a single step

- 粒子与粒子之间的碰撞无需移动部件即可获得优质产品

- 温度敏感产品的停留时间极短

- 气流粉碎原理可保持湿饲料中的颗粒分布

立式闪蒸干燥机

For temperature sensitive products where minimum heat input is desired

- Once-through flow of product protects temperature-sensitive material

- Product is evenly dispersed into hot air stream, providing uniform treatment

- Minimum operator attention required

- 垂直结构最大程度减少占地面积

- 可提供利用多种热源的直接和间接加热系统

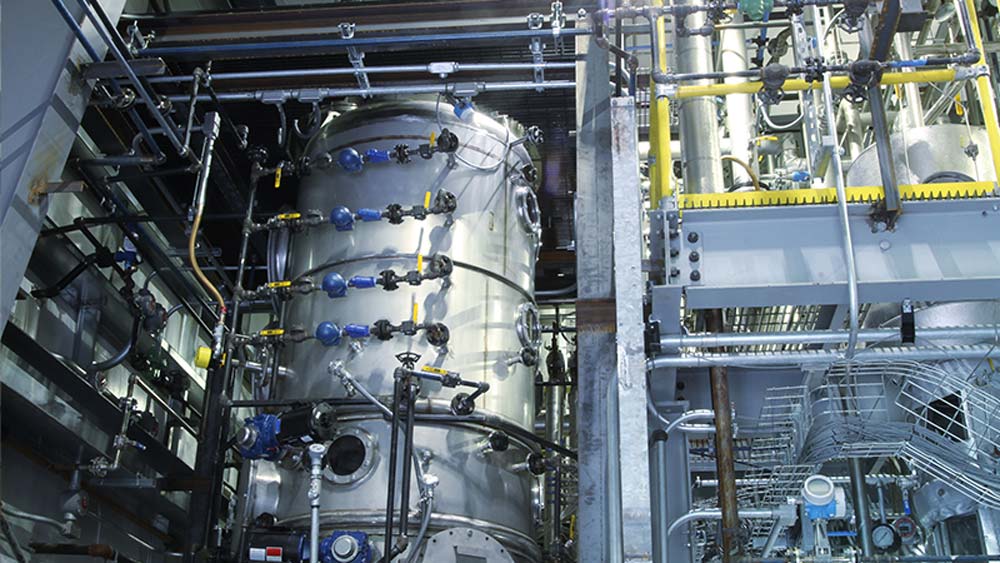

真空 Desolventizer 剥离器 (VDS)

Continuous indirect vacuum drying or desolventization for temperature-sensitive water- or solvent-wet products.

- 先进的干燥技术

- Low operating temperature

- 绝对压力为 200 mbar 的低压运行

- 保持颜色和功能

- Reduces energy consumption and operational costs

- Continuous operation ensures reliable and scalable drying process

真空干燥机

For heat sensitive products.

- For water- or solvent-wet products that can operate at pressures as low as 200 mbar absolute

- Helps maintain color and functionality on several protein products.

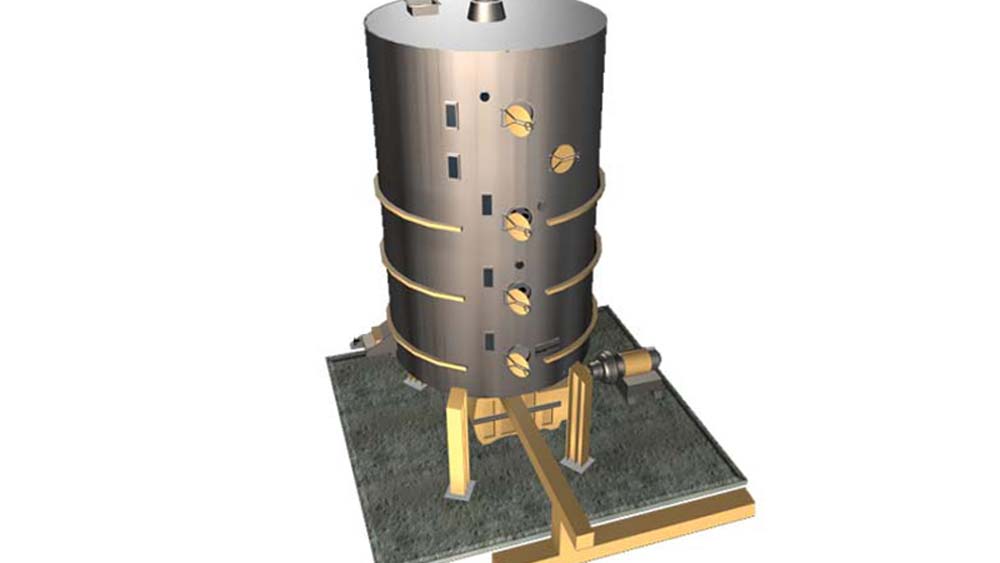

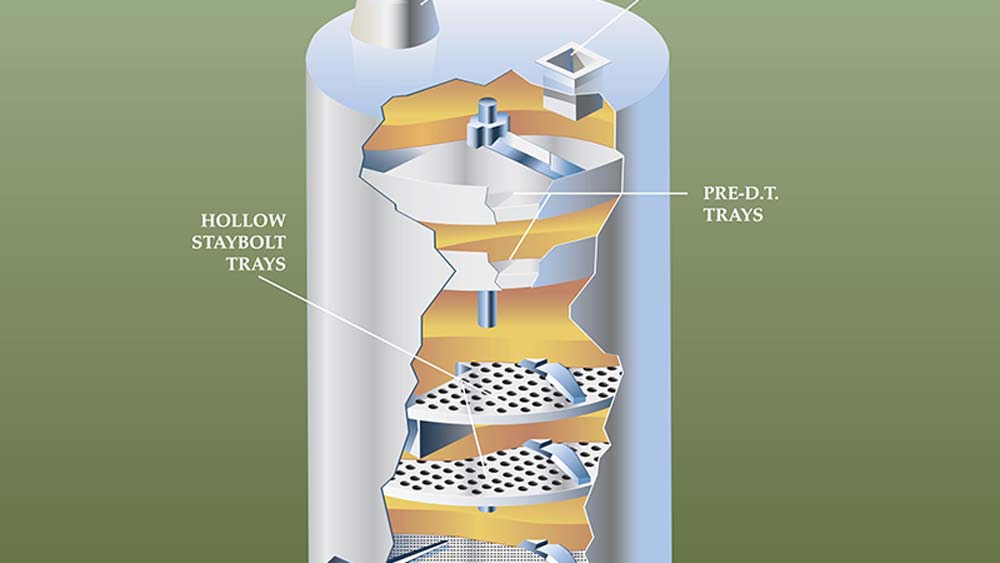

脱溶机

Vertically oriented cylinder with multiple trays to desolventize solvent-wet products on a low-cost basis.

- Employees indirect heat transfer to desolventize ethanol, hexane or other solvent-wet products

- 垂直多托盘设计最大程度减少占用空间

- 扫臂可防止大团块形成

- 可以在底部托盘中添加低压蒸汽或汽提气体,以清除材料周围的蒸汽空间

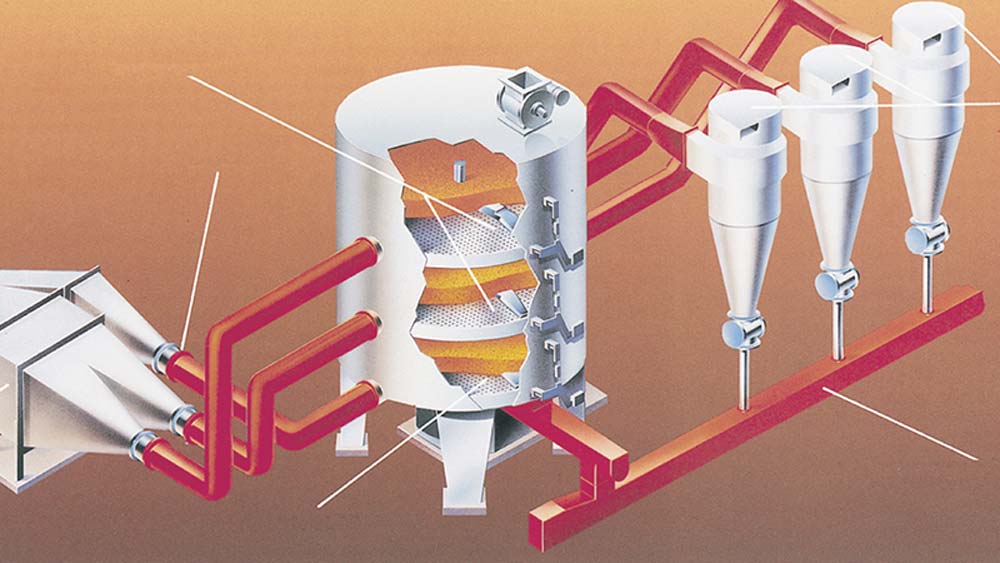

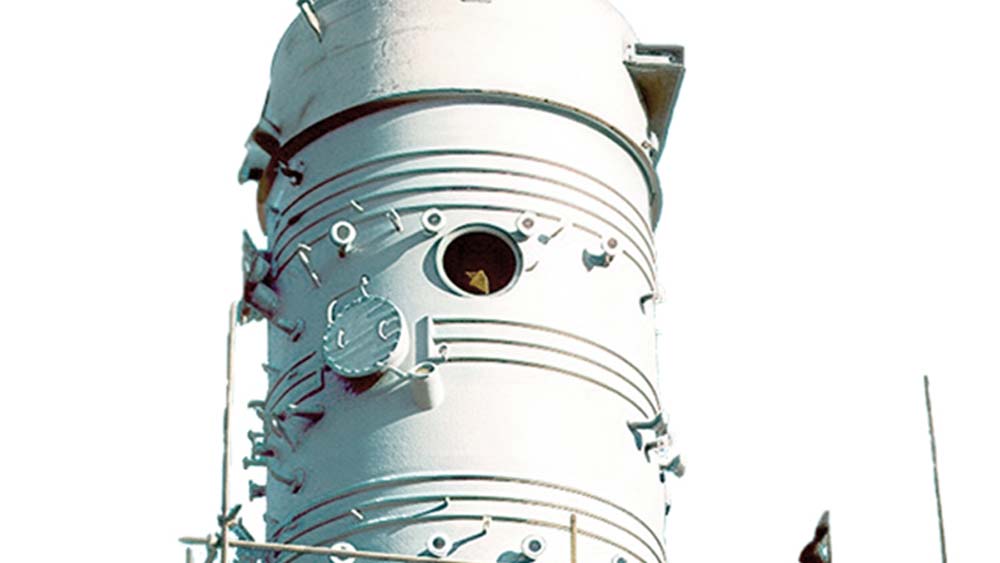

DTDC Desolventizer Dryer/Cooler

Vertically oriented tray/semi-fluid bed dryer for granular materials or flakes

- Uses significantly lower amount of steam and leads to distinctly lower solvent losses

- Automatic level controls and special chutes or variable speed rotary valves provide for smooth and efficient operation

- Low horsepower per ton requirements

- Heavy duty steam chests and robust computer designed sweep arms virtually eliminates sweep arm breakage and bending

- Low capital costs and space requirements

- Reduced meal dryer steam usage

- Capacities of over 9,000 MTPD of soybeans

Desolventizer Cooler (DC)

逆流系统可有效干燥和冷却您的产品。

- 垂直多托盘设计最大程度减少占用空间

- 表面坚硬的钢扫臂可延长使用寿命

- 自动门机制可调节,以便为每个托盘装入所需的餐食深度

- 重型闸门轴承和密封件可延长使用寿命并最大程度减少泄漏

- When used with the Desolventizer Toaster (DT), will dry and cool almost any solvent-extracted, vegetable-oil-bearing meal

Desolventizer 烤面包机(DT)

使用直接和间接热传递对您的产品进行脱溶剂的最具成本效益的方法。

- CPM|Crown DTs are available for pilot scale to large scale production capabilities

- 经营植物油籽、二氧化硅、DDG、海产品和各种其他产品

- 每吨马力要求低

- 直接和间接传热相结合可实现高效的脱溶机施胶

- 逆流脱溶

- 带有驱动闸门、溜槽或变速旋转阀的自动液位控制可确保平稳、高效的运行

下吸式 Desolventizer (DDD)

For larger particles that require extended residence times for drying

- 整个过程中的温和处理可产生具有最大数量的完整薄片和最少数量的细粉的最终产品

- 低资本投资

- 降低安装成本

- Low installed horsepower; less than 20hp for a 100-ton-per-day system

- 塞流最大程度减少停留时间的变化

- 比传统系统可达到更高的 PDI

- Minimizes breakage of material where size and shape needs to be maintained

Flash Desolventization System (FDS)

Direct contact system with full solvent recovery and very short residence times.

- 产品与过热溶剂直接接触,在几秒钟内闪蒸脱溶

- 最大程度减少产品变性和变色

- Applicable for solvent-laden materials

- 直接接触式气力输送干燥机

- Gentle enough for temperature-sensitive materials

- 设计简单,操作方便

- Vertically oriented for small footprint

真空剥离器

Efficiently remove solvent from your products.

- Designed to follow a primary desolventizer to strip away solvent to achieve low-solvent concentration

- When a high protein dispersibility index is required, will operate under vacuum to fully strip away the solvent without overheating the product

- 容器和系统设计最大限度地减少了系统中的空气泄漏,从而最大限度地减少了对植物矿物油系统的影响

- 坚固的真空密封设计

- 紧凑的设计

- Low solvent ppms with minimal hexane loss

白色片状脱溶

Efficient desolventization system for high PDI or NSI meal production.

- Series of heated trays maintains flake integrity while driving off hexane vapors with low-pressure indirect steam

- Gentle handing preserves the functional properties of temperature-sensitive products

- Compact design requires less floor space for installation

- Reduces solvent losses to less than 500 ppm

- Maintains flake integrity without breakage

- Low capital investment and operational savings