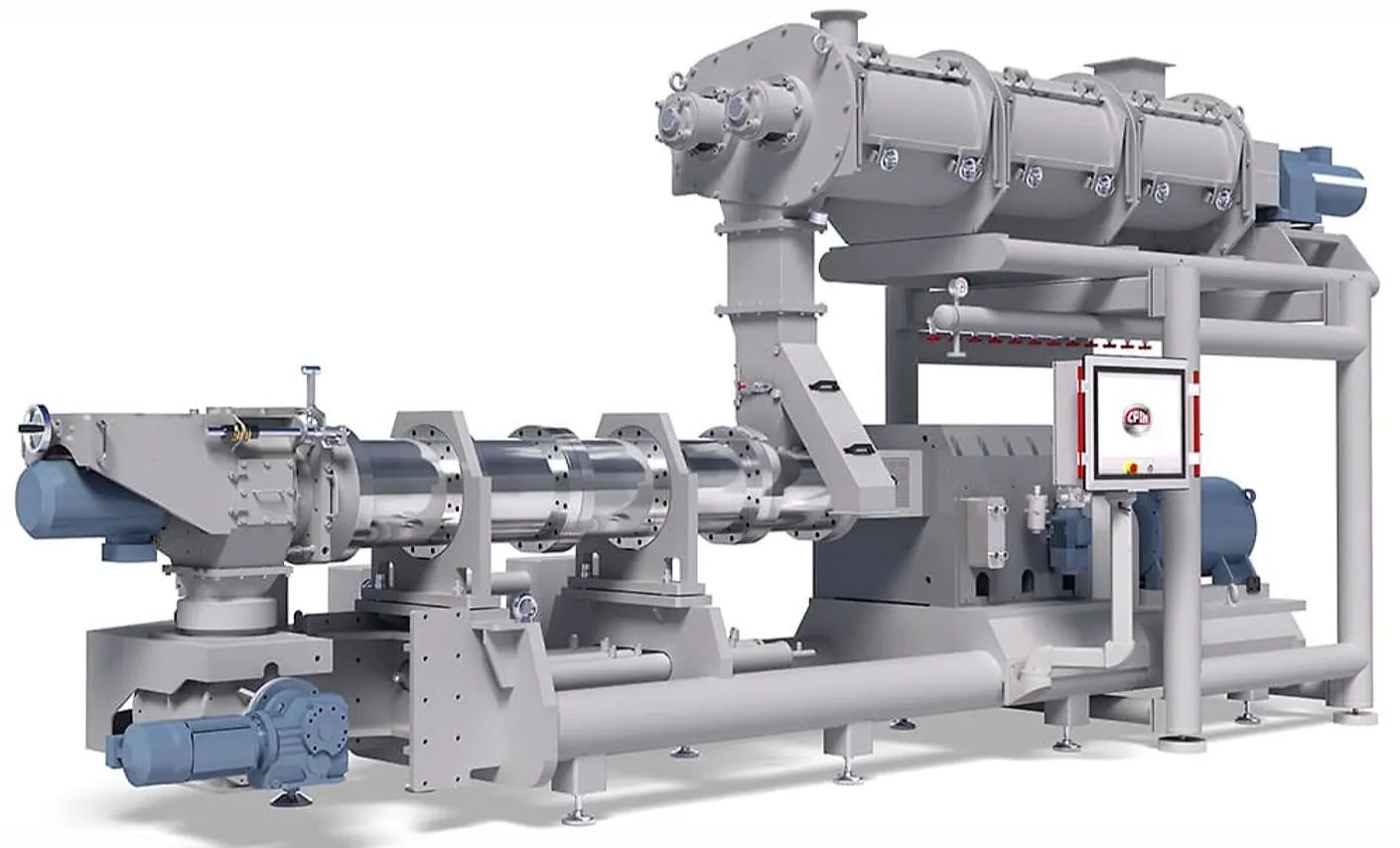

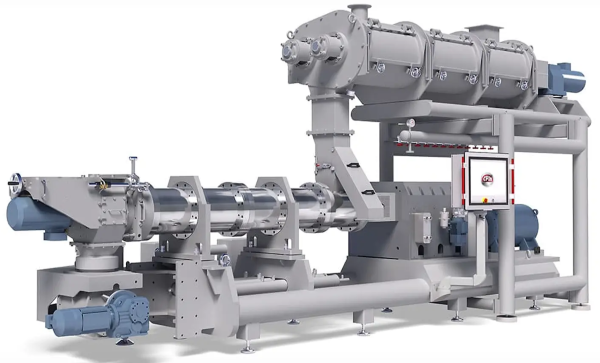

Density Control Unit

An optional feature, the density control unit, allows the TwinTech to produce different types of fish feed, including sinking and slow-sinking feeds, by using positive pressure inside the cutter chamber. This versatility allows manufacturers to produce a wide range of fish feed with a single machine.

Advanced Preconditioning and Cooking Systems

The TwinTech extruder introduces a new thermal hydrator and updates the differential diameter conditioner to improve the hydration and retention time of materials. These systems are designed to enhance the cooking process by ensuring efficient steam integration and retention, leading to better processing efficiency and product quality.