Cost-Effective

The GXT will lower your operational costs by fitting nearly all compounding applications, reducing the need for additional equipment.

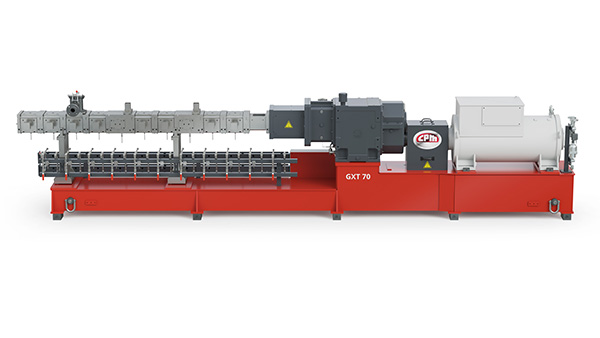

CPM offers two lines of twin-screw extruders, the GXT and the GXT Plus, providing manufacturers with the right balance of performance, flexibility, and cost efficiency. Whether you need a pre-engineered solution for standard applications or a customized extruder for specialized processing, CPM delivers reliable, high-quality systems backed by global support.

Combining the know-how and experiences from our locations all over the world, CPM has developed a standardized solution that can be applied worldwide. Introducing the Global eXtruder Technology (GXT). An Extruder that can be manufactured anywhere you are with the same specifications, same design, same support and same goal to advance your materials.

Available in 40 L/D or 48 L/D, it offers reliable performance, easy

integration, and minimal process adjustments, making it ideal for

both small manufacturers and large-scale operations managing

multiple extruders.

Key Features

The GXT will lower your operational costs by fitting nearly all compounding applications, reducing the need for additional equipment.

Choose from screw speeds of 300, 600, 900 or 1200 revolutions per minute.

Standard twin screw design to save space.

Our Innovation Lab can help you develop and optimize your processes.

| Model Size | Diameter (mm) | Center Distance (cm) | L/D Process Length | Max Screw Speed (RPM) | Specific Torque (N-m/cm^3) |

|---|---|---|---|---|---|

| GXT – 26 | 25 | 2.11 | 40/48 | 1200 | approx. 13 |

| GXT – 32 | 32 | 2.62 | 40/48 | 1200 | approx. 13 |

| GXT – 40 | 40 | 3.34 | 40/48 | 600-1200 | approx. 13 |

| GXT – 45 | 45 | 3.75 | 40/48 | 600-1200 | approx. 13 |

| GXT – 58 | 58 | 4.8 | 40/48 | 600-1200 | approx. 13 |

| GXT – 70 | 70 | 5.85 | 40/48 | 600-900 | approx. 13 |

| GXT – 92 | 92 | 7.6 | 40/48 | 600-900 | approx. 13 |

| GXT – 103 | 103 | 8.4 | 40/48 | 600-600 | approx. 13 |

| GXT – 119 | 118 | 9.7 | 40/48 | 300-400 | approx. 13 |

| GXT – 133 | 133 | 11 | 40/48 | 300-400 | approx. 13 |

application – industries

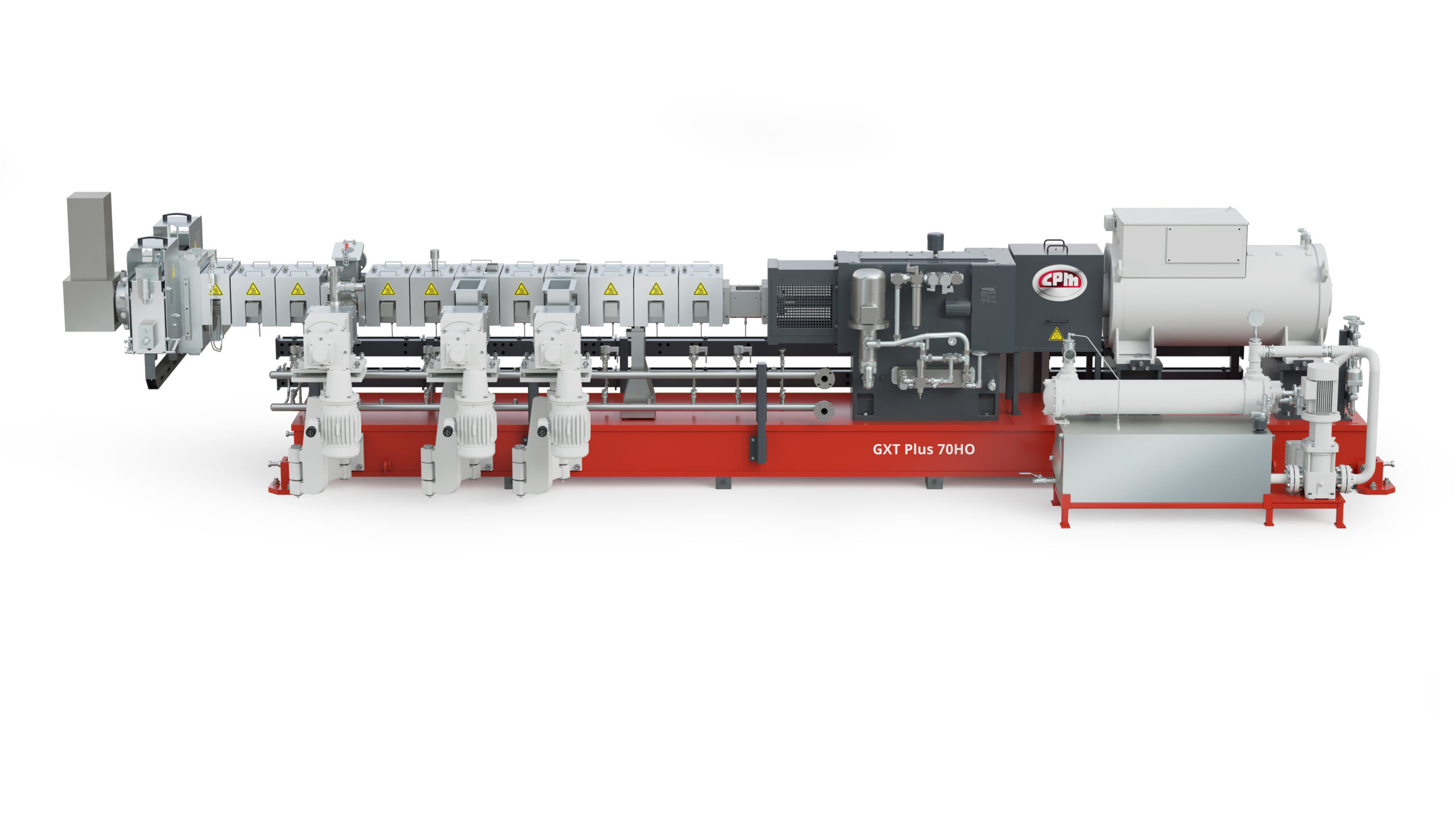

For customers requiring enhanced customization, the GXT Plus provides application-specific modifications such as specialized metallurgy for high-wear environments, additional process controls, and extended venting or side-feeding

options.

It delivers the same reliability as the GXT but with greater adaptability for complex compounding needs.

Together, these features ensure high reliability, process visibility, and operational efficiency for demanding compounding applications.

| Model Size | Diameter (mm) | Center Distance (cm) | L/D Process Length | Max Screw Speed (RPM) | Specific Torque (N-m/cm^3) |

|---|---|---|---|---|---|

| GXT – 26 PLUS | 25 | 2.11 | 36/60 | 1200 | 18> 13 |

| GXT – 32 PLUS | 32 | 2.62 | 36/60 | 1200 | 18> 13 |

| GXT – 40 PLUS | 40 | 3.34 | 36/60 | 600-1200 | 18> 13 |

| GXT – 45 PLUS | 45 | 3.75 | 36/60 | 600-1200 | 18> 13 |

| GXT – 58 PLUS | 58 | 4.8 | 36/60 | 600-1200 | 18> 13 |

| GXT – 70 PLUS | 70 | 5.85 | 36/60 | 600-1200 | 18> 13 |

| GXT – 92 PLUS | 92 | 7.6 | 36/60 | 600-900 | 18> 13 |

| GXT – 103 PLUS | 103 | 8.4 | 36/60 | 600-900 | 18> 13 |

| GXT – 119 PLUS | 118 | 9.7 | 36/60 | 300-600 | 18> 13 |

| GXT – 133 PLUS | 133 | 11 | 36/60 | 300-600 | 18> 13 |

application – industries

Complete Your Solutions

From global parts and service support to advanced automation systems, CPM keeps your operations running smoothly, efficiently and without interruption.