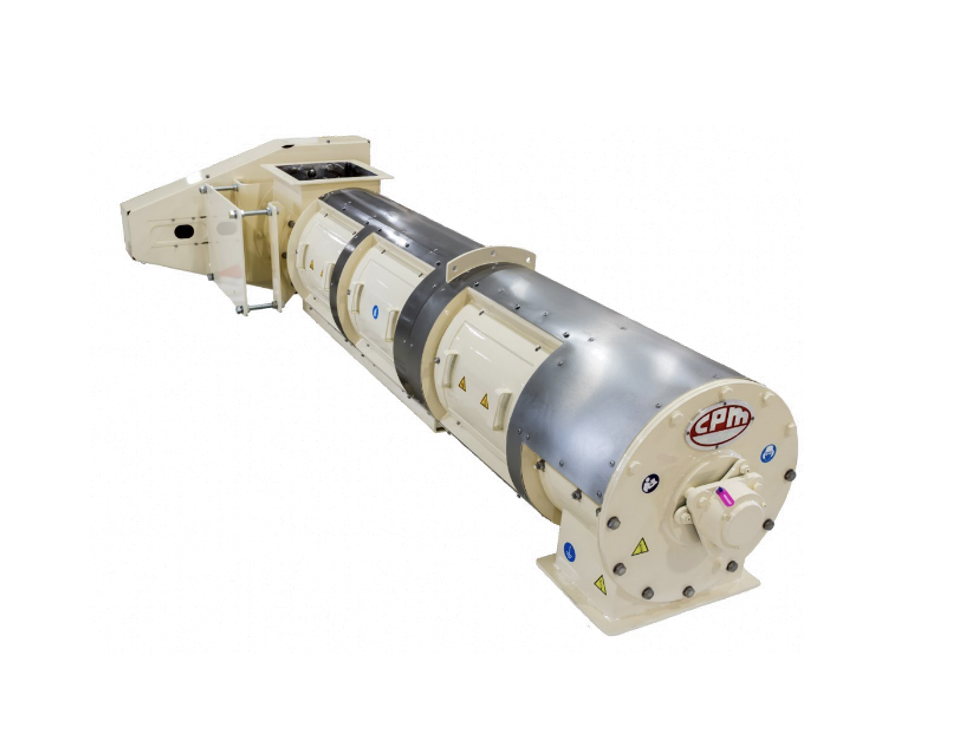

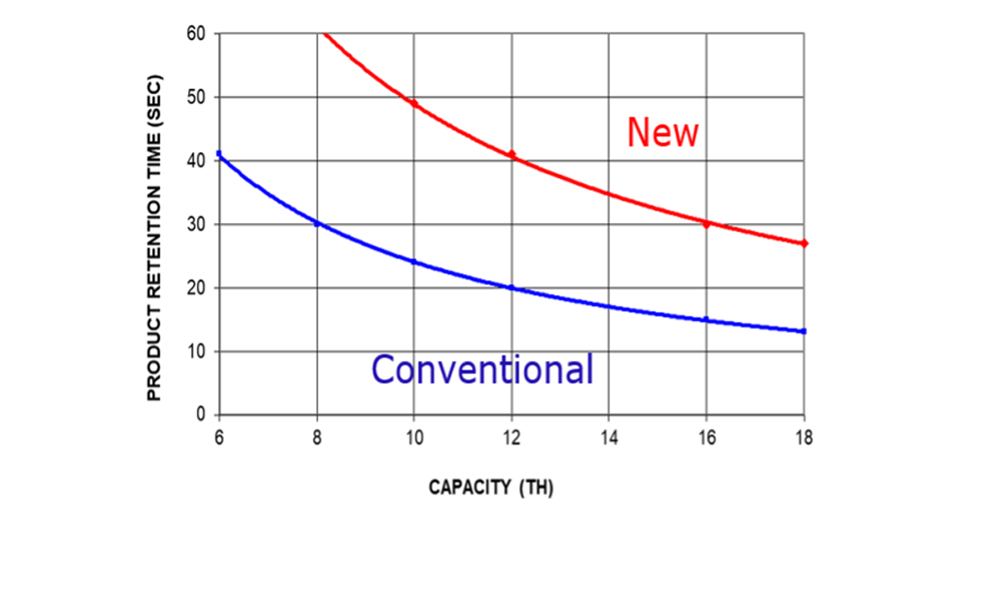

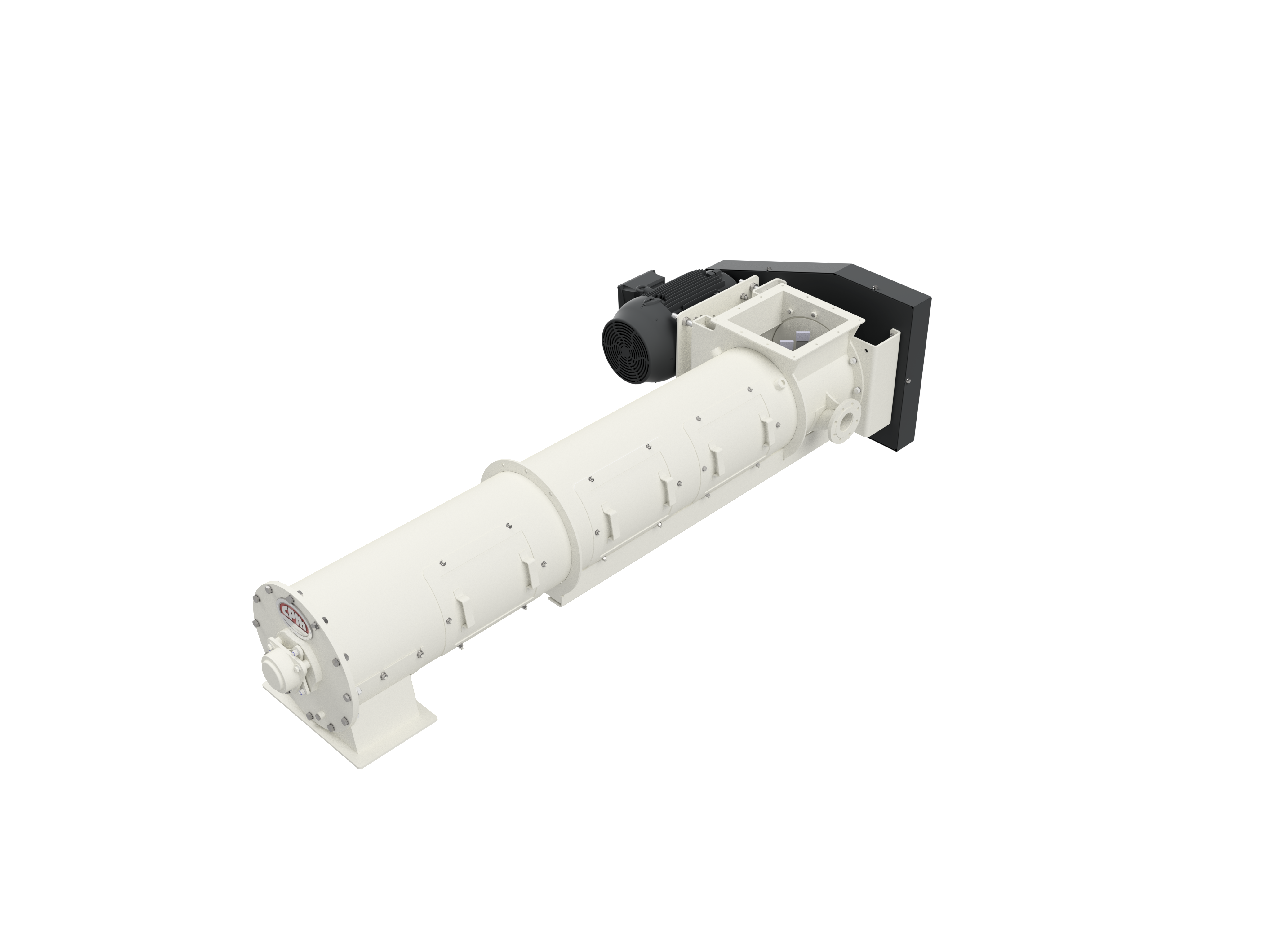

Explore solutions using the New Technology Conditioners

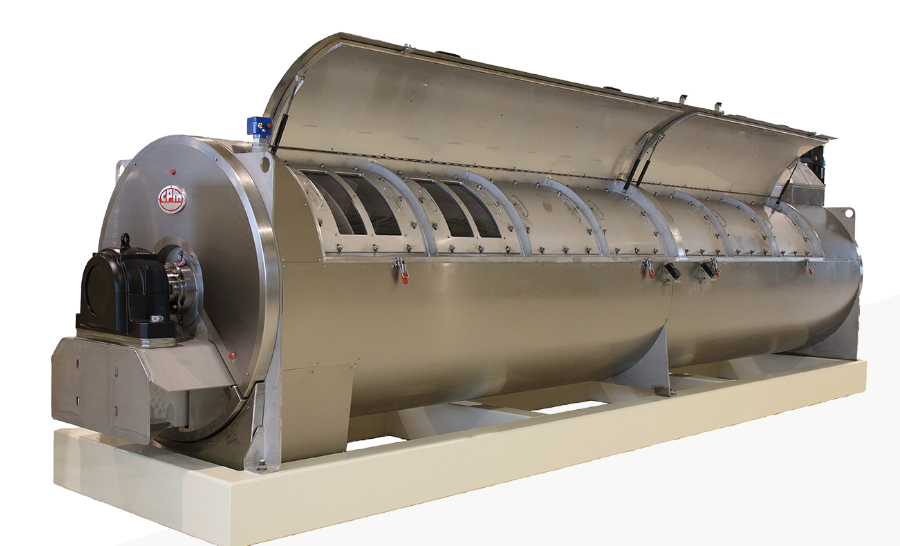

Not all processing conditions are identical. At CPM, we know that different materials require different conditioning. Because the needs and configurations of a process plant vary, CPM conditioners are custom manufactured to your plant’s needs.

Explore All Solutions