Easy to Clean

Sanitary, easy-to-clean designs also provide access for maintenance

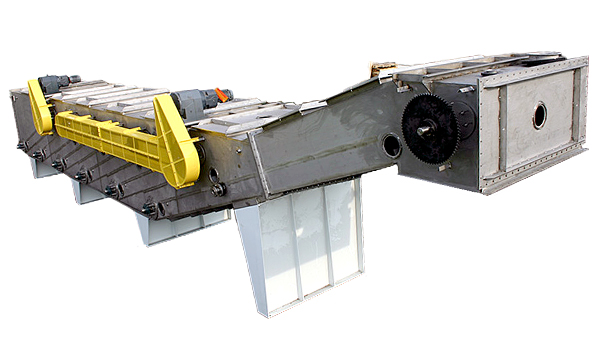

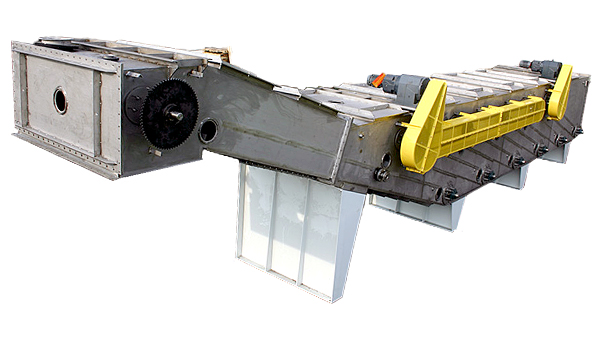

For granular or coarse products, such as metallic gels, algae and marine products that sink in solvent or products that are too fine or coarse for percolation-type extractors, the Model IV Extractor processes virtually any product with a density greater than the solvent. Typical products include algae, hemp, hemp seeds, botanicals, fermentation products, metallic gels and contaminated soils.

In the past, the extraction of fine, powdery material was usually carried out in a batch process due to the limitation of screen filtration in continuous extractor designs. Basically, fine materials would flow through the screen. But the Model IV doesn’t use screens. The basic horizontal fabrication houses a unique, patented “en-masse” type conveyor system, which draws the material along the smooth extractor bottom. There, it is totally immersed in solvent flowing from the other direction. This means there is no problem keeping the solids wetted.

Extraction occurs throughout the cycle as the material and miscella are mixed between stages. This counter-current arrangement allows the extracted material to be discharged from one end of the machine while concentrated miscella (solvent and extractable) is taken from the opposite end.

Key Features

Sanitary, easy-to-clean designs also provide access for maintenance

Time-proven design for alcohols, hydrocarbons, and other solvents

Complete testing facilities and rental equipment available for testing and small production

Continuous operation requires minimal operator attention

Features

The Model IV Extractor can tackle your toughest extracting challenges, like granular and coarse products including gels, algae, and other marine products.

Complete Your Solutions

From global parts and service support to advanced automation systems, CPM keeps your operations running smoothly, efficiently and without interruption.