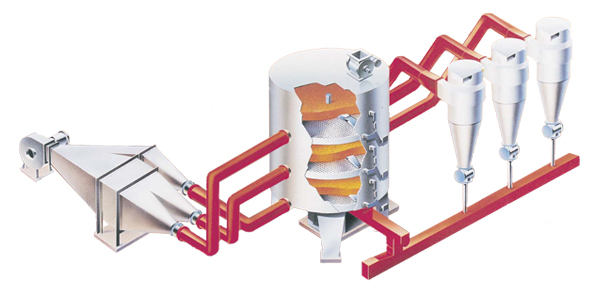

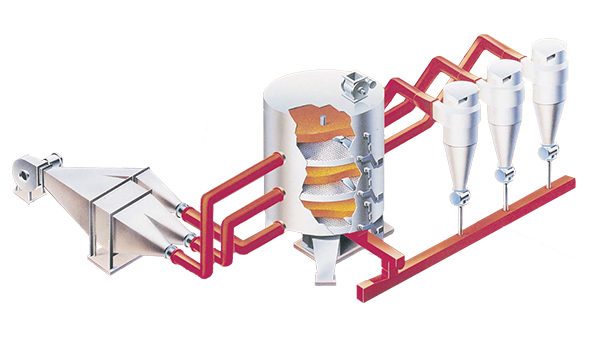

Small Footprint

Vertical multiple tray design minimizes footprint.

The Dryer-Cooler (DC), when used with the Desolventizer-Toaster (DT), will dry and cool almost any solvent-extracted, vegetable-oil-bearing meal. The drying and cooling is accomplished by injecting heated air in the drying section and using ambient-temperature air to cool the meal in the cooling section. The evenly distributed flow of hot air and cool air in a true counter-current system is highly efficient and reduces energy costs while producing a meal with the desired characteristics for sale and storage.

The DC unit works equally well combined with a DT or used as a separate unit, depending upon customer preference.

The DC used in a specialty application is a direct contact dryer that uses the heat and water in the product to dry and simultaneously cool the product with minimal air.

Key Features

Vertical multiple tray design minimizes footprint.

Automatic gate mechanisms are adjustable for loading each tray with the desired depth of meal.

Quick-opening round manholes for easy access and tight closure.

Complete Your Solutions

From global parts and service support to advanced automation systems, CPM keeps your operations running smoothly, efficiently and without interruption.