Advanced Catalyst Reduction & Economization (ACRE)

Process upgrade for biodiesel manufacturers.

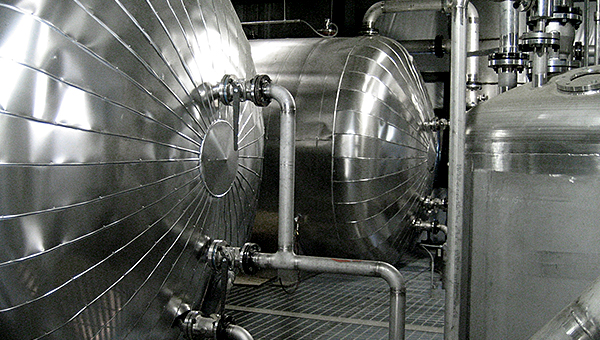

Backed by our expertise in biodiesel processing, CPM’s Crown Advanced Catalyst Reduction & Economization (ACRE) enables biodiesel manufacturers to run at the lowest operating cost and highest efciency by adding a third transesterifcation reaction step while also delivering an energy effcient design for reduced cooling load and steam use.

- Reduced acid usage

- Energy savings through economization

- Reduced load on cooling and heating systems

- Increased uptime

- Minimal plant disruption – short implementation time can be coordinated with annual shutdowns

- Proven in multiple geographies

- Consistent biodiesel quality

- Higher quality glycerin with less salt content

Key Features

- Successfully running in multiple plants and yielding impressive results, and with multiple feedstocks

- Plants in production achieving 40%+ catalyst reduction and experiencing $ .03 savings per gallon.

- Easily retrofitted into any unmodified CPM Crown plant and available for centrifuge operations

- Ideal for greenfield installations to improve performance and total cost of ownership

Complete Your Solutions

Full Lifecycle Solutions

From global parts and service support to advanced automation systems, CPM keeps your operations running smoothly, efficiently and without interruption.

Automation