Solutions

Complete Processing Solutions

for Pet Food Producers

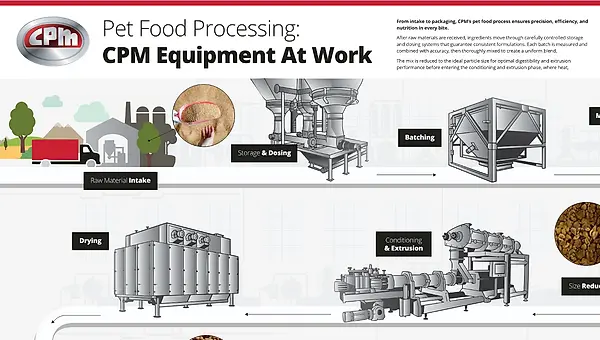

At CPM, we provide pet food manufacturers with a full line of high-quality processing equipment, innovative solutions and unparalleled support to produce best in class kibble and treats with consistent texture, shape and nutritional profile.

Pet Food Solutions to Keep You Moving

From standard dry kibble to premium, our equipment is engineered to allow us to offer cost-competitive solutions without compromising on quality. Whether you need to optimize your existing process or build a new production line, we provide everything from aftermarket support to

automation — making us your single-source solutions provider for pet food processing.

Mixing Solutions

The Twin Shaft Paddle Mixer is used for dry mixing and wet mixing for granular and powder material. The paddle design ensures high mixing action with uniform and homogenous distribution of important nutrients, vitamins, and minerals in the pellet mixture.

This mixer is used for the incorporation of different powder and granular ingredients, with or without the addition of liquid in food, premix, pet food, aqua feed, and animal feed production.

Improve the quality of your product while shortening your mixing time with the Twin Shaft Paddle Mixer. This versatile mixer offers optional replaceable and adjustable paddle angles, and is easy to clean thanks to pre-assembled spray nozzles with compressed air for pipe maintenance.

Why Choose CPM:

- Protect product quality with short mixing time and low shear from the twin paddle design.

- Deliver consistent results with high mixing efficiency and homogeneity (C.V. 3%–5%).

- Enhance hygiene thanks to optimized paddle-to-wall gap design.

- Minimize waste with large double “bomb” doors for low-residue discharge.

- Reliable and flexible transmission via V-belt, with optional direct drive and gearbox system.

- Easy liquid addition and cleaning with optional pre-installed spray nozzles and compressed air cleaning system.

- Support ingredient versatility with a loading grate for solid or semi-solid additions during mixing.

- Customizable performance with optional adjustable, replaceable paddles.

- Durable and adaptable construction in mild steel or optional double-walled stainless steel for material-contact surfaces.

Grinding Solutions

When it comes to grinding in pet food production, performance matters. Our hammermills are built to thrive in the most demanding applications—offering consistent results, durable construction, and exceptional ease of use. Whether you’re producing kibble or specialty pet food formulas, our hammermills deliver the efficiency and precision required to reduce particles exactly how you need them.

HM Series Hammermills

- Rugged, high-density frame to reduce vibration and noise.

- Air-swept teardrop design with patented regrind chamber.

- Customizable configurations for coarse to fine grinding.

- One-piece full-access doors on pivoting arms for easy service.

- Designed for friable and fibrous materials alike.

EMF Series (Eliminator Fine Grind)

- Designed to bridge the gap between standard. hammermills and fine grinders.

- Capable of producing 40–100 mesh granulations.

- High-efficiency grinding for enhanced output and product uniformity.

ER Series Hammermills

- Built for difficult-to-grind materials (fatty, oily, sticky, or flow-resistant).

- Specialized design prevents clogging and allows for extra fine grinding.

- Quick and easy wear part replacement for reduced downtime.

- Robust construction to handle the toughest applications.

Why Choose CPM:

- Flexible Production: Customize grind sizes and handle a wide variety of ingredients, including challenging formulations.

- Higher Efficiency: Achieve finer grinds with less energy, boosting output and lowering operational costs.

- Minimized Downtime: Full-access doors and easy-change wear parts speed up maintenance and reduce production interruptions.

- Superior Durability: Built to last, even in the most demanding pet food applications.

- Backed by Industry Expertise: With CPM support, you get more than a machine—you gain a long-term partner in production success.

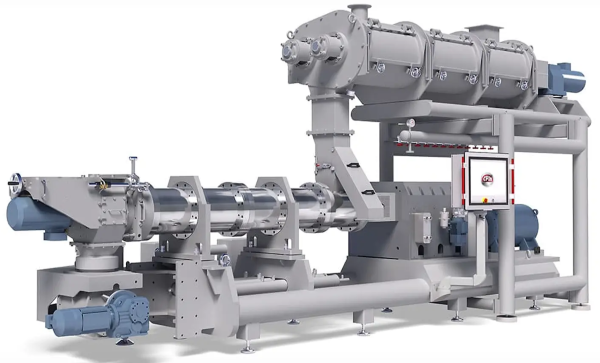

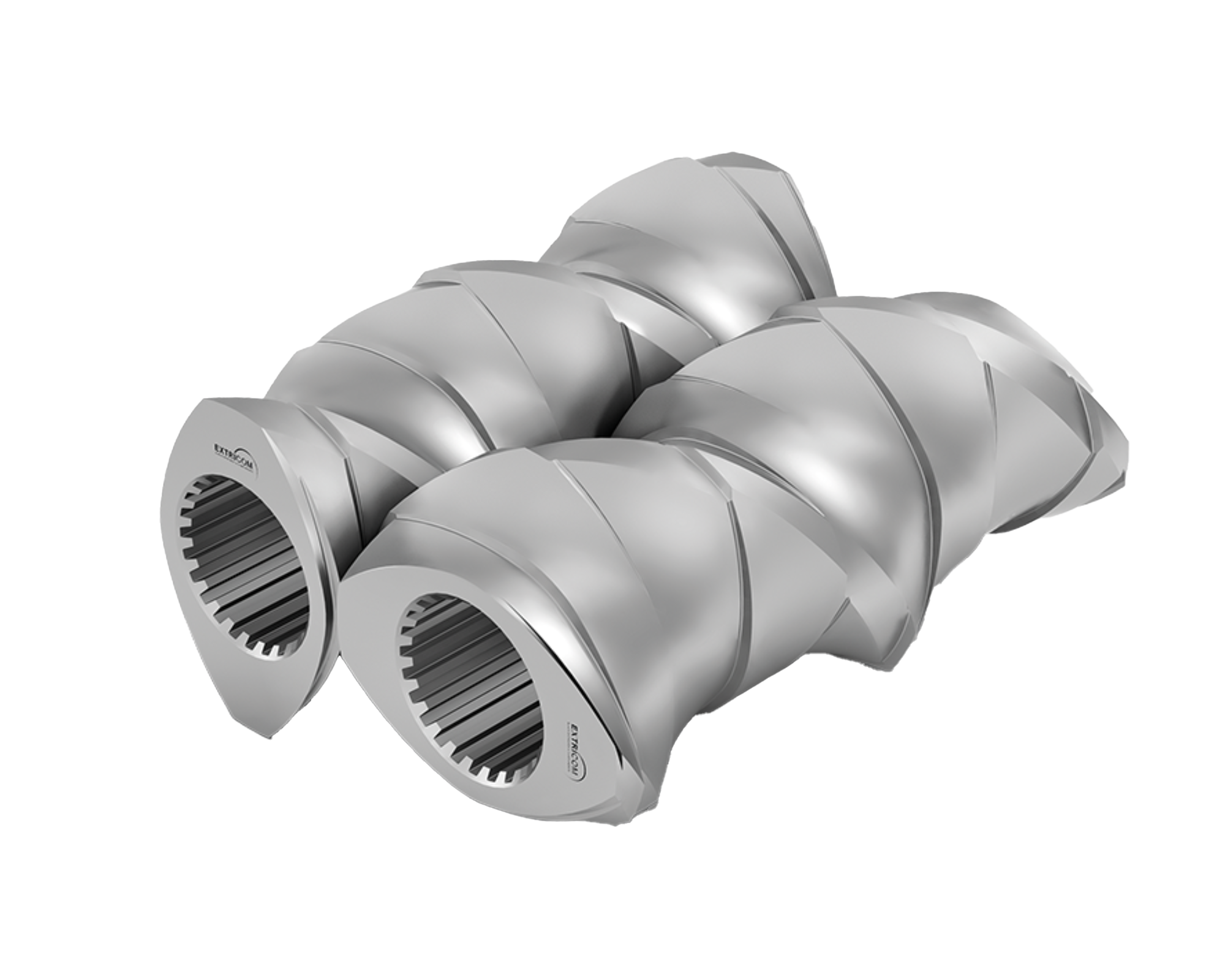

Extrusion Solutions

- Energy-Efficient Design: Powered by a permanent magnet synchronous motor (PMSM) that is 50% smaller than traditional air-cooled motors. Reduces energy consumption, lowering operating costs while maintaining high performance.

- Enhanced Gearbox Technology: High-speed, heavy-duty gearbox for increased processing capacity and efficiency. Designed for reliability with a torque limiter for mechanical safety.

- Single Source Provider: From extrusion to drying, coating, automation, and aftermarket services, we provide everything you need for seamless pet food production.

- Global Support: CPM’s parts and service team is there when you need them to keep your production line at its best.

- Automation at its finest: Enhance production efficiency and leverage real-time operational insights to optimize your process.

- Innovation Center: Test, refine and perfect recipes and manufacturing processes before full-scale production.

Why Choose CPM:

- Reduce operating costs and save space without sacrificing performance through compact, power-saving PMSM technology.

- Maximize throughput and protect your investment with a high-capacity gearbox built for durability and safety.

- Simplify your operations with a fully integrated solution from one trusted partner for the entire pet food production line.

- Keep your line running at peak performance with fast, reliable service and parts—wherever you are.

- Boost efficiency and make smarter decisions with real-time data and advanced process control.

- Accelerate development with hands-on testing before going to full production.

Drying Solutions

- Precise Moisture Control & Consistency: Minimal moisture variance to ensure uniform product quality and shelf stability.

- Easy to operate & Hygienically Designed: Accessible, modular and user-friendly design reduces downtime, while dust collection and discharge solutions ensure cleaner, safer production environment.

- Energy Efficiency: High-efficiency heat exchanger provides better heat transfer, reducing energy use while maintaining optimal processing conditions and reducing costs.

- Flexible Heating Options: Gas and steam options, offering versatility to fit different processing setups.

Why Choose CPM::

- Achieve uniform product quality and extended shelf life with tightly controlled moisture levels.

- Minimize downtime and maintain a cleaner, safer environment with a user-friendly, modular design and built-in dust management.

- Lower energy costs while maintaining ideal processing conditions through an advanced heat exchanger system.

- Adapt easily to your facility’s infrastructure with the choice of gas or steam heating configurations.

Coating Solutions

CPM’s coating systems are designed to efficiently apply liquid ingredients—up to 30% inclusion—to pet food, fish feed, and livestock feed. These ingredients are absorbed either by penetrating the product’s pores or coating its surface, depending on the application. This process ensures precise, even distribution of critical additives that enhance both nutritional value and product appeal.

Whether you’re boosting palatability, improving shelf life, or enhancing the nutritional profile of your feed, CPM coating technology delivers the consistency and efficiency manufacturers need.

Why Choose CPM:

- Enhance nutritional content by precisely applying oils, vitamins, enzymes, and other sensitive ingredients post-extrusion.

- Boost palatability to improve taste appeal and encourage repeat consumption.

- Extend shelf life with even coating coverage that supports better preservation.

- Maximize product value by upgrading standard kibbles into premium offerings.

- Drive profitability through value-added processing that increases market appeal.

- Ensure coating consistency with advanced technology that delivers uniform coverage across every batch.