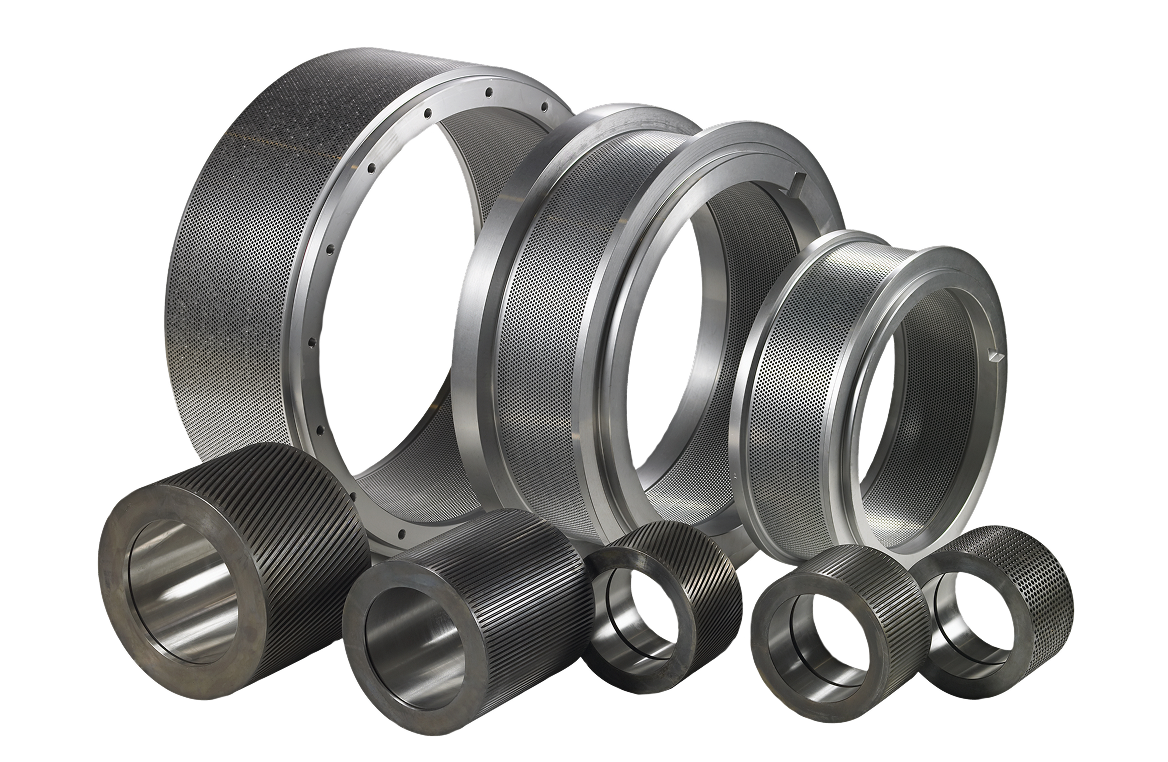

Matched to Your Mill. Built to Last.

Every process demands a different profile. Whether you’re chasing higher compression, longer wear, or better traction—we’ve got the roller shell to get it done.Our shells fit all major pellet mill brands—not just CPM.

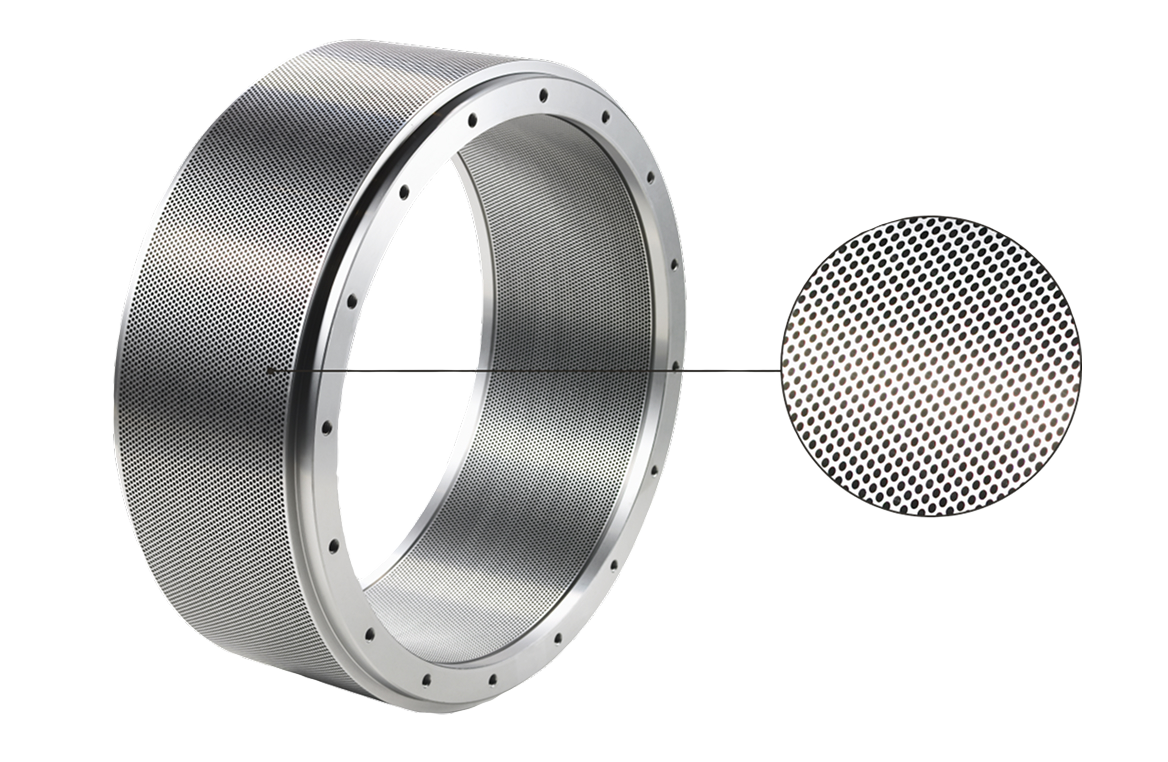

Available Profiles:

● Dimple – Balanced performance

● Corrugated – Grip under load

● Pinnacle™ – Optimized for throughput

● Dominator™ – Tough feeds, tougher shells

● Tungsten Coated – Maximum wear resistance