Achieve the highest-quality, solvent-free end product – regardless of input – when you partner with CPM|Crown. As a leader in oilseed extraction for 75+ year, we provide the technical expertise, guidance and proven technologies to improve current processes and develop new products. Meet all your needs with our full range of drying and desolventization equipment, including continuous vacuum dryers and energy-efficient vertical dryers.

For every application, a proven solution.

CONTACT A DRYING/DESOLVENTIZATION EXPERTSPECIALTY DRYING & DESOLVENTIZATION

High-performance drying and desolventization for every application.

Milling Flash Dryer

No moving parts—for applications where a fine end-product is desired

- Delivers a fine end product that does not require further milling

- Dry and de-agglomerate in a single step

- Particle-to-particle collisions achieve fine products without moving parts

- Extremely short residence times for temperature-sensitive products

- Jet milling principles preserve particle distribution present in wet feed

Vertical Flash Dryer

For temperature sensitive products where minimum heat input is desired

- Once-through flow of product protects temperature-sensitive material

- Product is evenly dispersed into hot air stream, providing uniform treatment

- Minimum operator attention required

- Vertical construction minimizes floor space

- Can provide direct and indirect heating systems using a variety of heat sources

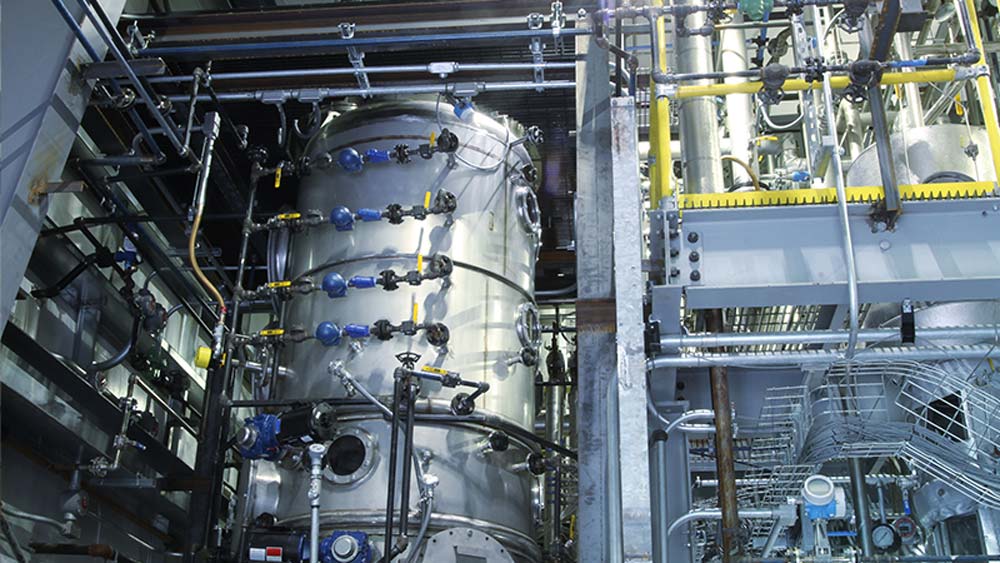

Vacuum Desolventizer Stripper (VDS)

Continuous indirect vacuum drying or desolventization for temperature-sensitive water- or solvent-wet products.

- Advanced drying technology

- Low operating temperature

- Low-pressure operation at 200 mbar absolute

- Maintains color and functionality

- Reduces energy consumption and operational costs

- Continuous operation ensures reliable and scalable drying process

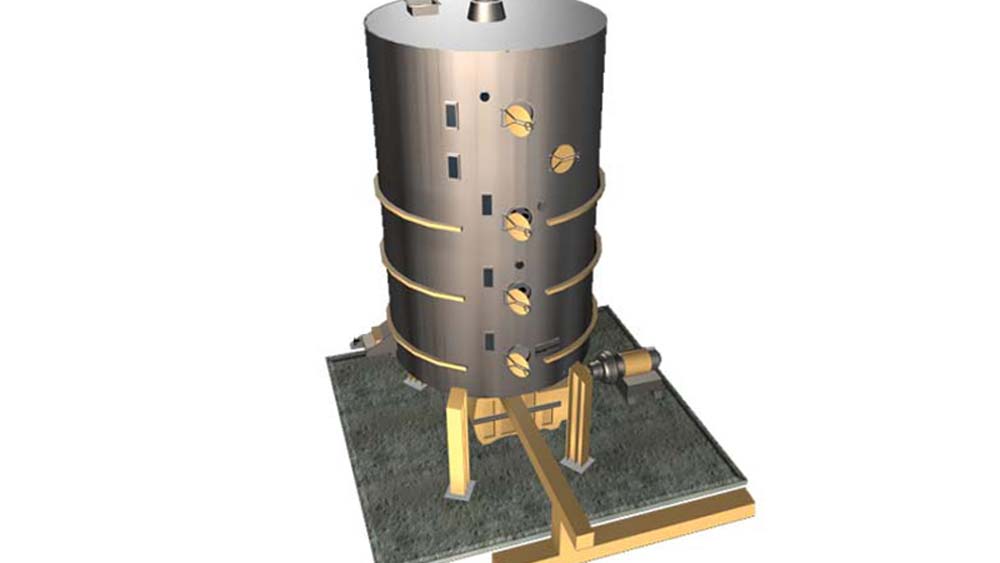

Vacuum Dryer

For heat sensitive products.

- For water- or solvent-wet products that can operate at pressures as low as 200 mbar absolute

- Helps maintain color and functionality on several protein products.

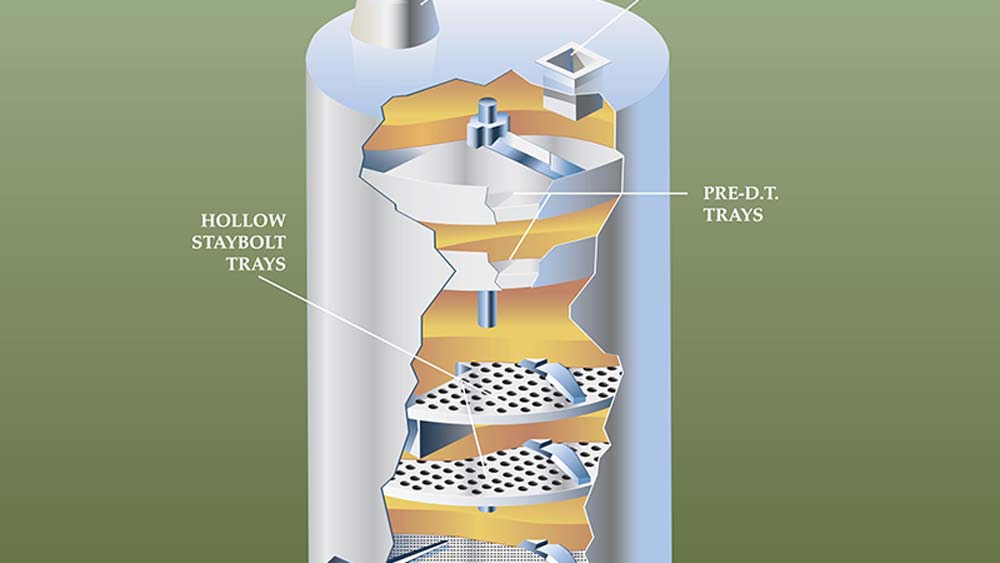

Desolventizer

Vertically oriented cylinder with multiple trays to desolventize solvent-wet products on a low-cost basis.

- Employees indirect heat transfer to desolventize ethanol, hexane or other solvent-wet products

- Vertical, multiple-tray design minimizes footprint

- Sweep arms prevent large agglomerates from forming

- Low-pressure steam or stripping gases can be added in the bottom tray to clear the vapor spaces surrounding the material

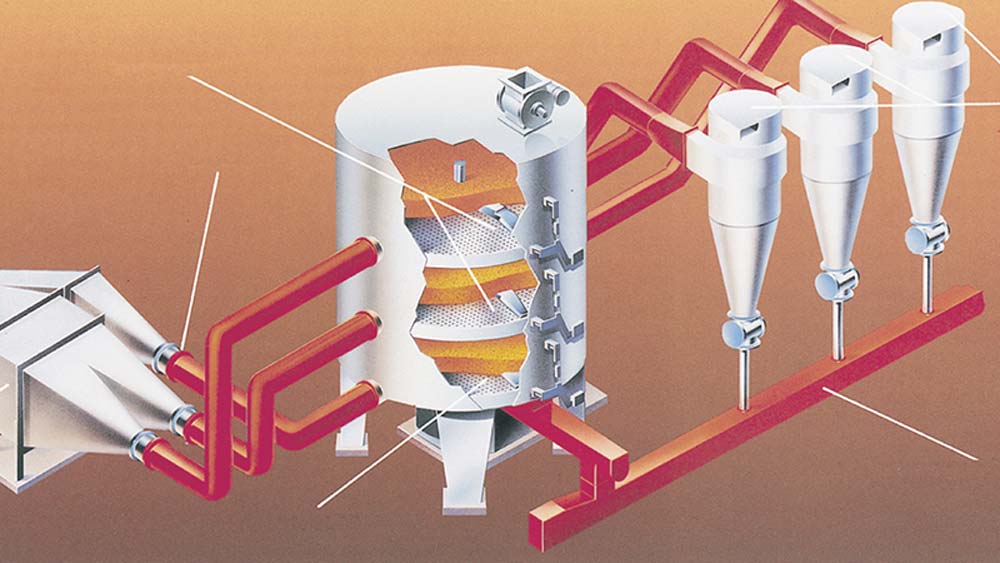

DTDC Desolventizer Dryer/Cooler

Vertically oriented tray/semi-fluid bed dryer for granular materials or flakes

- Uses significantly lower amount of steam and leads to distinctly lower solvent losses

- Automatic level controls and special chutes or variable speed rotary valves provide for smooth and efficient operation

- Low horsepower per ton requirements

- Heavy duty steam chests and robust computer designed sweep arms virtually eliminates sweep arm breakage and bending

- Low capital costs and space requirements

- Reduced meal dryer steam usage

- Capacities of over 9,000 MTPD of soybeans

Desolventizer Cooler (DC)

A counter-current system to efficiently dry and cool your products.

- Vertical multiple tray design minimizes footprint

- Hard-surfaced steel sweep arms for longer wear

- Automatic gate mechanisms are adjustable for loading each tray with the desired depth of meal

- Heavy-duty gate bearings and seals for long wear and minimum leakage

- When used with the Desolventizer Toaster (DT), will dry and cool almost any solvent-extracted, vegetable-oil-bearing meal

Desolventizer Toaster (DT)

The most cost-effective way to desolventize your products using direct and indirect heat transfer.

- CPM|Crown DTs are available for pilot scale to large scale production capabilities

- Operates on vegetable oilseeds, silicas, DDG, marine products and a wide variety of other products

- Low horsepower-per-ton requirements

- Combination of direct and indirect heat transfer leads to efficient desolventizer sizing

- Counter-current desolventization

- Automatic level controls with actuated gates, chutes or variable speed rotary valves provide for smooth and efficient operation

Down Draft Desolventizer (DDD)

For larger particles that require extended residence times for drying

- Gentle handling throughout the process produces a final product with a maximum amount of whole flakes and a minimum amount of fines

- Low capital investment

- Lower installation costs

- Low installed horsepower; less than 20hp for a 100-ton-per-day system

- Plug flow minimizes variation in residence time

- Higher attainable PDI than with conventional systems

- Minimizes breakage of material where size and shape needs to be maintained

Flash Desolventization System (FDS)

Direct contact system with full solvent recovery and very short residence times.

- Product is in direct contact with superheated solvent to flash-desolventize the product in seconds

- Minimal product denaturization and discoloration

- Applicable for solvent-laden materials

- Direct contact pneumatic conveying dryer

- Gentle enough for temperature-sensitive materials

- Simple design and easy operation

- Vertically oriented for small footprint

Vacuum Stripper

Efficiently remove solvent from your products.

- Designed to follow a primary desolventizer to strip away solvent to achieve low-solvent concentration

- When a high protein dispersibility index is required, will operate under vacuum to fully strip away the solvent without overheating the product

- Vessel and system design minimizes in-leakage of air into the system, minimizing the effect on plant mineral oil systems

- Robust vacuum seal design

- Compact design

- Low solvent ppms with minimal hexane loss

White Flake Desolventization

Efficient desolventization system for high PDI or NSI meal production.

- Series of heated trays maintains flake integrity while driving off hexane vapors with low-pressure indirect steam

- Gentle handing preserves the functional properties of temperature-sensitive products

- Compact design requires less floor space for installation

- Reduces solvent losses to less than 500 ppm

- Maintains flake integrity without breakage

- Low capital investment and operational savings